Thread Callout On Drawing

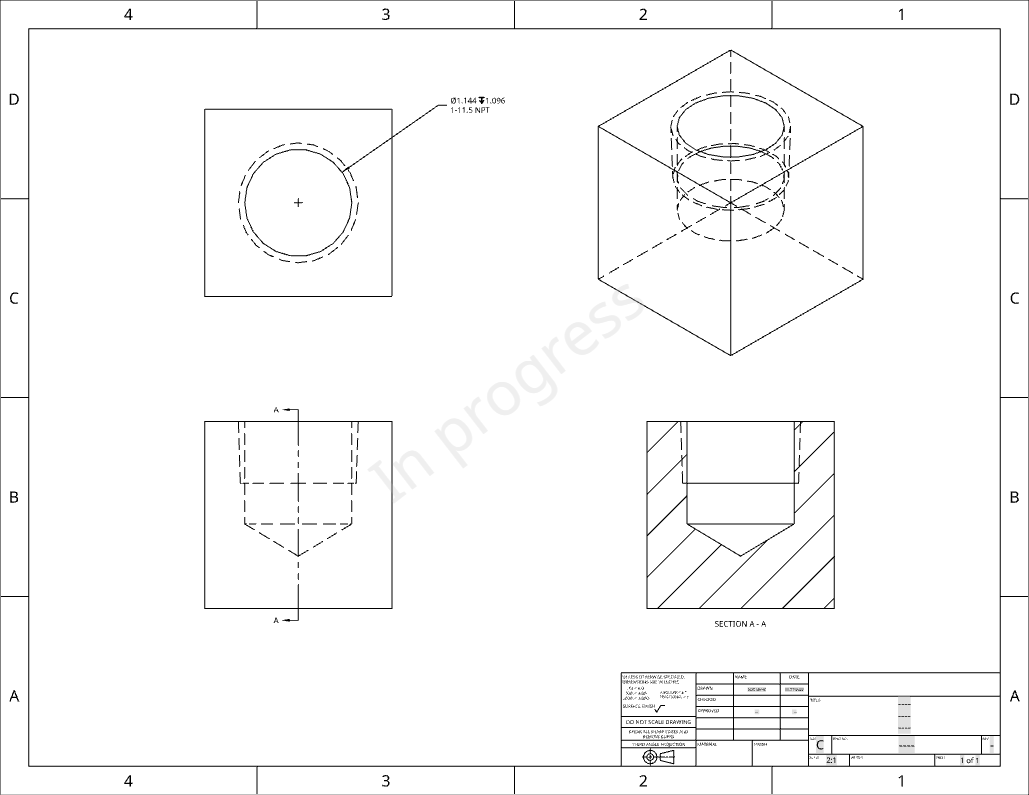

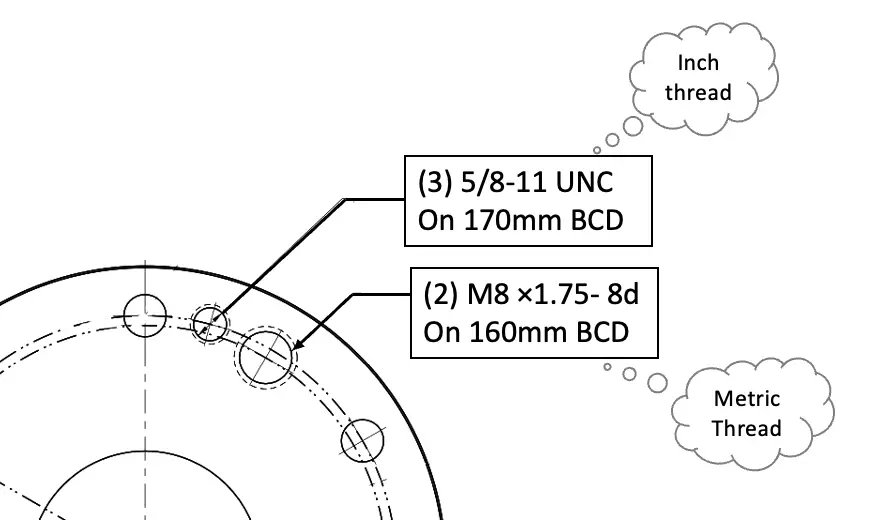

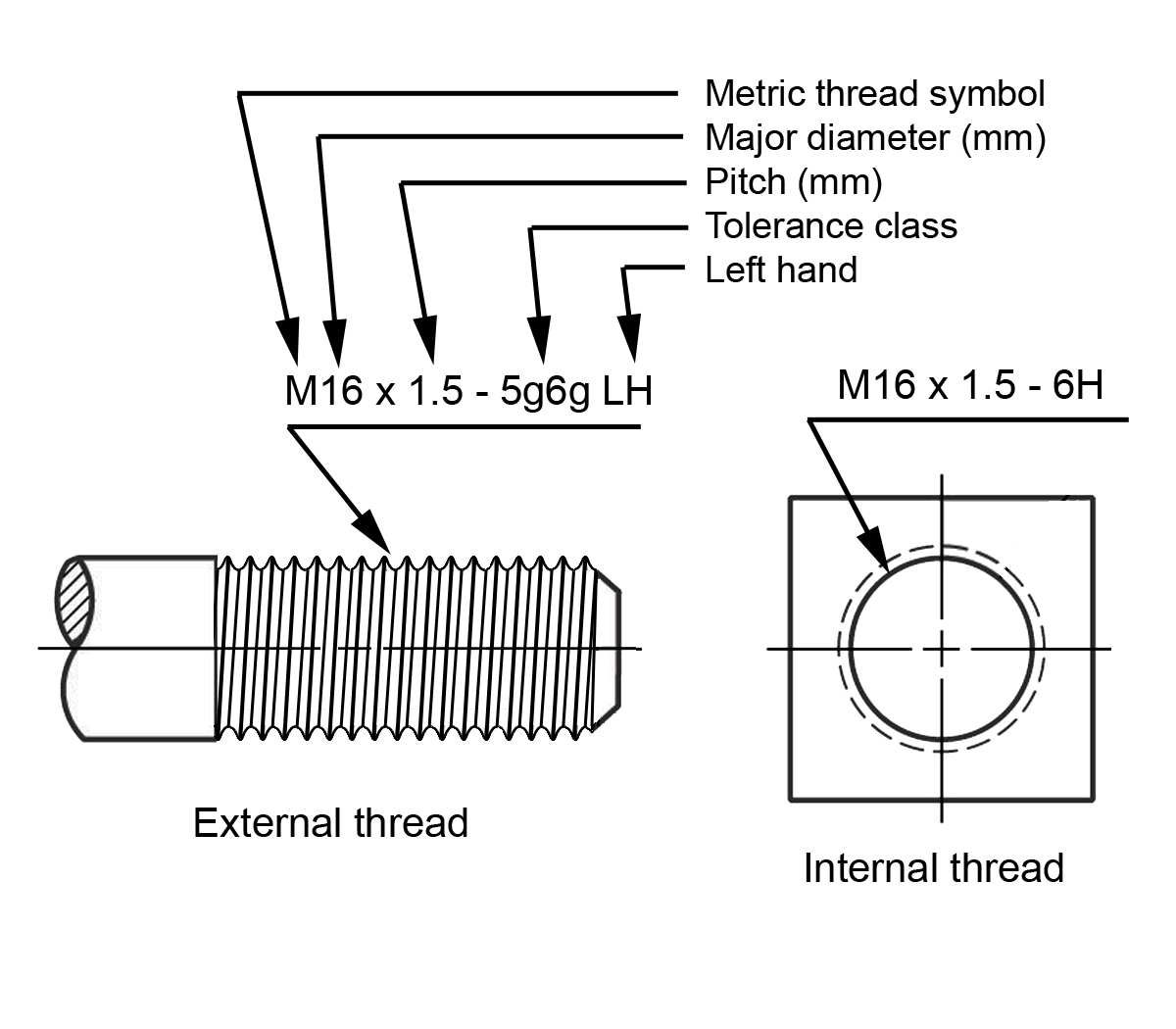

Thread Callout On Drawing - All i can find in my references are a minumum nominal size, threads per inch, thread form and thread class. Web to add the callout: Look at the numbers in the callout. It is usually not printed on the screw. Web there are three methods of representing screw threads on a drawing. Let us discuss how to read screw thread designation from the hole or shaft. Min full thread is sloppy and unnecessary because the thread depth callout fully defines acceptable limits for the threads. A callout indicating that the pipe tap should be driven until just 6 full threads are left on the tap. Need to tap a hole with this type of thread. We recommend providing detailed thread callouts, as. Web this specification provides drawing callout information and dimensions and tolerances for torch cut & drilled thru holes and drilled & tapped threaded holes. Look at the numbers in the callout. For example, if i call out a. You have to look for a label. Web here are the five steps to interpreting thread callout: This gives us just the right. Web sometimes it’s quite confusing to read the hole thread designation on the drawings. It is usually not printed on the screw. I think it got a little confusing. We recommend providing detailed thread callouts, as. Web sometimes it’s quite confusing to read the hole thread designation on the drawings. Web there are three methods of representing screw threads on a drawing. Web it's metric, 16mm with a pitch of 1.0mm. Web to add the callout: Web here are the five steps to interpreting thread callout: You have to look for a label. Let us discuss how to read screw thread designation from the hole or shaft. The difference is one group says also call out diameter of the hole to be drilled to prepare for tapping, second group says don't include diameter of the hole, the. Web just a suggestion that works for us. Look. Local notes (callouts) 2 2 3 4. Look at the numbers in the callout. All i can find in my references are a minumum nominal size, threads per inch, thread form and thread class. Web this specification provides drawing callout information and dimensions and tolerances for torch cut & drilled thru holes and drilled & tapped threaded holes. Web threads. Web the thread callout is a bit lacking, you may have noticed the lh designator is not an option either, even though it is an option when you create the thread. Web threads appear as dashed lines at the top of the cylindrical face in drawings. Look for a label with the callout printed on it. Web threads should be. Screw thread representation present in this chapter is in accordance with. Descriptions of the thread series: Web 1.drilling and tapping drilling and tapping is one of the most common and traditional methods for creating threaded holes. Look for a label with the callout printed on it. The difference is one group says also call out diameter of the hole to. Screw thread representation present in this chapter is in accordance with. Web threads should be defined by indicating a standard thread size (for example m4x0.7) instead of a diameter dimension. Web to add the callout: Let us discuss how to read screw thread designation from the hole or shaft. Web here is my specific question about the two schools of. Local notes (callouts) 2 2 3 4. Web 1.drilling and tapping drilling and tapping is one of the most common and traditional methods for creating threaded holes. You have to look for a label. Web here is my specific question about the two schools of thought, using a typical thread callout. Web threads effect of thread angle on strength: This method is widely used for materials such as. I think it got a little confusing. Web here are the five steps to interpreting thread callout: Click smart dimension (dimensions/relations toolbar) or tools > dimensions > smart. All i can find in my references are a minumum nominal size, threads per inch, thread form and thread class. Let us discuss how to read screw thread designation from the hole or shaft. Web good afternoon i have a question regarding hole callouts for a threaded hole with a counterbore where does the depth of the thread start is it from the top surf. This gives us just the right. Need to tap a hole with this type of thread. This method is widely used for materials such as. Web here are the five steps to interpreting thread callout: All i can find in my references are a minumum nominal size, threads per inch, thread form and thread class. Look at the numbers in the callout. Web the thread callout is a bit lacking, you may have noticed the lh designator is not an option either, even though it is an option when you create the thread. A callout indicating that the pipe tap should be driven until just 6 full threads are left on the tap. Web there are three methods of representing screw threads on a drawing. It is usually not printed on the screw. Click smart dimension (dimensions/relations toolbar) or tools > dimensions > smart. Web it's metric, 16mm with a pitch of 1.0mm. Web to add the callout: Local notes (callouts) 2 2 3 4.

Hole/Thread Callout

Threaded Hole Callout Standard Home Interior Design

Threaded Hole Callout Standard Home Interior Design

How to Read Screw Thread Designation? ExtruDesign (2022)

Using Cosmetic Threads in SOLIDWORKS Parts and Drawings

Dimensioning threaded fasteners Engineering Design McGill University

Understand The Threaded Hole Callout Standard

3D Printing Threads (Cosmetic/Virtual Threads vs Real 3D Threads)

Thread callout in drawing Siemens UG/NX EngTips

Dimensioning threaded fasteners Engineering Design McGill University

Web Just A Suggestion That Works For Us.

Web Threads Appear As Dashed Lines At The Top Of The Cylindrical Face In Drawings.

Web Sometimes It’s Quite Confusing To Read The Hole Thread Designation On The Drawings.

Web Threads Effect Of Thread Angle On Strength:

Related Post: