Sheet Metal Drawings

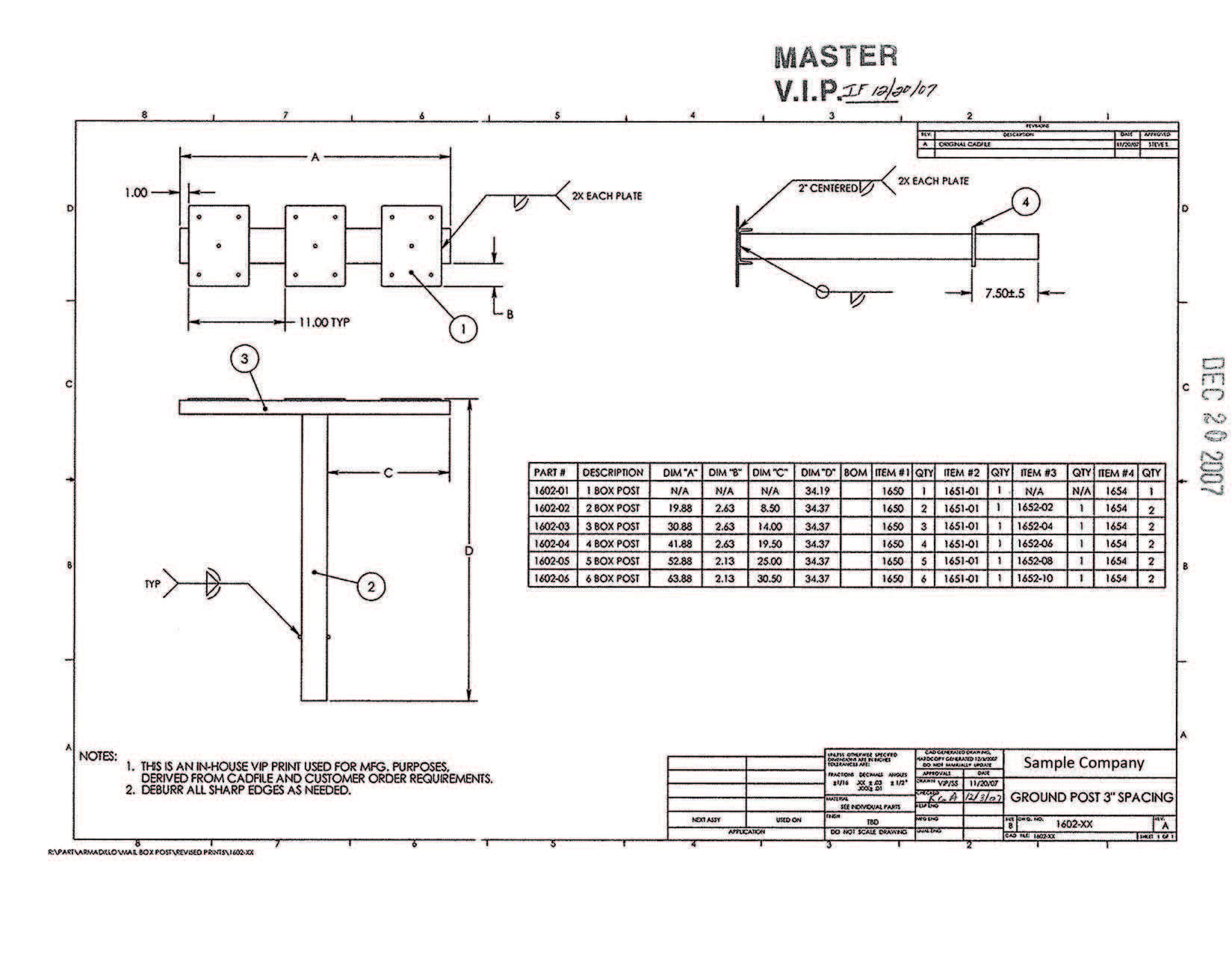

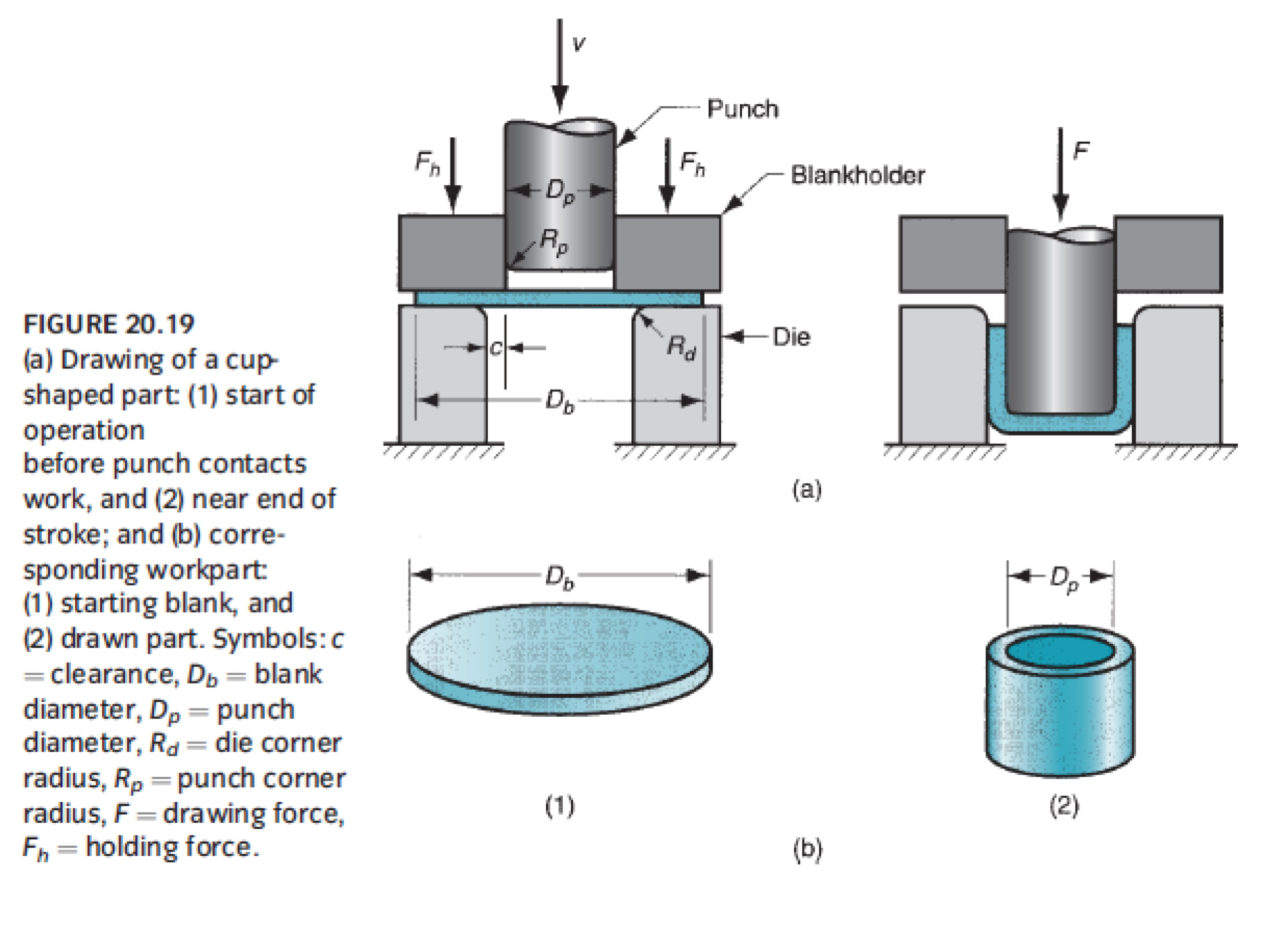

Sheet Metal Drawings - Web develop sheet metal models with fewer steps. Web solidworks tutorial sheet metal drawings. Web extracting drawings from the sheet metal part all together, these tasks should take about 15 minutes to complete. When creating drawing views of sheet metal models you can select the folded model or the flat pattern. Effortlessly create sheet metal models from 2d sketches, and work directly with geometry. 3d cad files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. It is a best practice to dimension to virtual intersection points and. Drawings of sheet metal parts can also contain views of the bent sheet metal part. When using the insert bends or convert to sheet metal features, apply the features as early Web inventor sheet metal drawings. Sheet metal parts are known for their durability, which makes them great for end use applications. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. Web for your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices for drawing reviews, so. 3d cad files are converted into machine code, which controls a machine to precisely cut and form the sheets into the final part. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Sheet metal shop drawings are detailed technical drawings that provide instructions and information for the fabrication and assembly of sheet metal. Include grain direction as needed; All of your sheet metal dfm work will be wasted if you can’t communicate the requirements of your parts to. Web following are the 9 different types of sheet metal operations: Web for your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices. This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Effortlessly create sheet metal models from 2d sketches, and work directly with geometry. • display a flattened view, in addition to other design views, in a single drawing. Web following are the 9 different types of sheet metal operations:. Effortlessly create sheet metal models from 2d sketches, and work directly with geometry. When creating views of flat patterns take note of the options to include the bend extents and punch centers. This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Drawings of sheet metal parts can also. Use the convert to sheet metal feature. This allows engineers and designers to create precise models of sheet metal components. Web for your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices for drawing reviews, so you can catch any last minute mistakes before your parts are released.. Provide details for revision control; • show one or more bend notes as you would a drawing annotation. The orthographic drawing was created from the 3d. These drawings are typically created by engineers or draftspersons and used by sheet metal fabricators to produce accurate and. • display a flattened view, in addition to other design views, in a single drawing. Shop drawings should be created by someone in the company familiar with detailing. Use the convert to sheet metal feature. In this tutorial video we will learn how to sketch sheet metal drawings in solidworks with the help of sheet metal tools. Web a fully dimensioned drawing including dimensions for formed bends, countersinks, holes, flanges. For someone who may be. • show one or more bend notes as you would a drawing annotation. All of your sheet metal dfm work will be wasted if you can’t communicate the requirements of your parts to. D = 2.5t + r (see below) the height can be less but it required secondary operations and is far more costly. This article endeavors to demystify. When creating views of flat patterns take note of the options to include the bend extents and punch centers. Include grain direction as needed; A title block with your company name, part number, part description, scale, tolerances, units, etc. Web the art of drawing metal sheets has enabled revolutionary advancements in design paradigms and provided pathways for improved functional capabilities.. When creating views of flat patterns take note of the options to include the bend extents and punch centers. Shop drawings should be created by someone in the company familiar with detailing. This allows engineers and designers to create precise models of sheet metal components. 55k views streamed 4 years ago. All of your sheet metal dfm work will be wasted if you can’t communicate the requirements of your parts to. Sheet metal shop drawings are detailed technical drawings that provide instructions and information for the fabrication and assembly of sheet metal components. Web for your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices for drawing reviews, so you can catch any last minute mistakes before your parts are released. Web sheet metal drawings are detailed as any other creo parametric drawing. Web a fully dimensioned drawing including dimensions for formed bends, countersinks, holes, flanges. List part numbers, not just the part name; This article endeavors to demystify the intricate domain of sheet metal drawing, focusing specifically on its more specialized variant, deep drawing. Use the convert to sheet metal feature. It is an essential aspect of manufacturing in various industries, such as automotive, aerospace, construction, and consumer products. When you create a drawing of your sheet metal part, a flat pattern is automatically created. Web for a slot or hole > 1 diameter then the minimum distance d = 2.5t + r (see fig. Web sheet metal design software like autodesk fusion 360 includes a combination of 2d and 3d design capabilities.Sheet Metal Practice Drawing

Solidworks Tutorial Sheet metal drawings YouTube

sheet metal drawings for practice pdf sketchuptutorialspart2

sheet metal drawings for practice pdf Alyse Britton

Autodesk Inventor Sheet metal Drawing Tutorial Basics YouTube

Sheet Metal Drawing Pdf EASY DRAWING STEP

Sheet Metal Practice Drawing

Metal Drawings at Explore collection of Metal Drawings

Basics of Sheet Metal Design Consumer Hardware Guide Hardware FYI

Sheet Metal Shakotis

2 Sheet Metal Design For.

Web Drawings Of Sheet Metal Parts.

This Tutorial, Which Is Common To The Sheet Metal Design User's Guide And To The Generative Sheet Metal Design User's Guide, Is Illustrated Using Screen Captures From The Sheet Metal Design Workbench.

Effortlessly Create Sheet Metal Models From 2D Sketches, And Work Directly With Geometry.

Related Post: